The use of a hammer and chisel allowed artisans of the past to shape and carve marble into a variety of forms and patterns. It was strenuous work, and most people in this day and age probably would not want to wait three years for their marble countertops to be hand-crafted by a craftsman. Things have improved significantly since we last saw them. It is likely that an up-to-date marble cutter can complete your work.

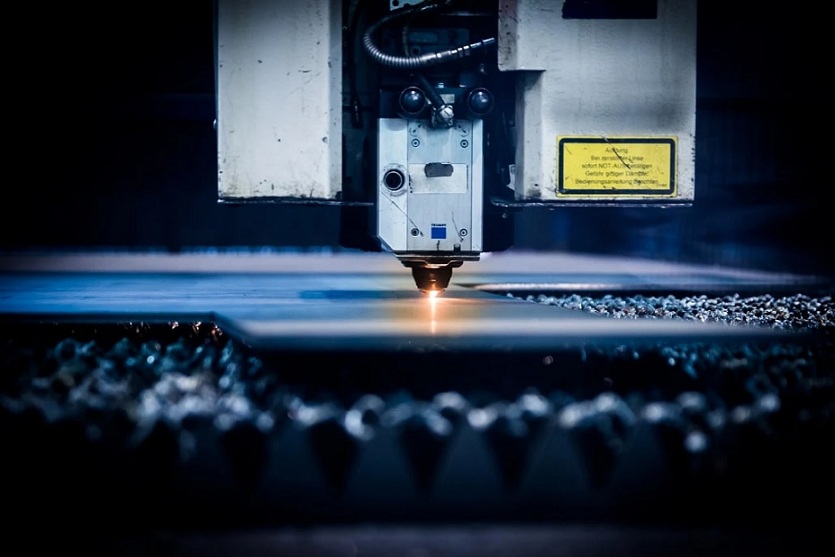

When the machine is all set up and ready to go, you look at the pattern that you are going to cut out. First, you use a forklift to load the stone into your machine, and then you use the control panel to instruct the machine how to make the appropriate cuts. You let the machine do the work while you stand nearby, ready to provide assistance in case there are any issues. Stone is a mineral that occurs naturally that is created deep down. Stone can be broken up into smaller pieces. It is a common material for use in landscaping projects and, depending on the stone’s hardness, can be sculpted using a diverse set of cutting implements.

The use of CNC cutting equipment allows the natural stones to be sculpted into a variety of jalis, each of which will unquestionably contribute to the allure of your wall. The use of a CNC cutter for Jali and Lattice patterns comes with a number of advantages. Designs using Jali or lattice can stand the test of time, which is one of its benefits. Another advantage is the fact that they do not negatively impact the environment. The creation of Jali patterns does not involve any actions that are detrimental to the natural world. In addition to this, it offers excellent value for the money. The best quality Marble Cutting Blade helps the CNC machine to cut the stones easily.

Several design experts have erroneous beliefs about the computer numerical control (CNC) process, despite the fact that CNC has many benefits. The widespread belief that CNC technology is primarily utilized for working with granite slabs ranks among the most common myths. It is frequently impossible to imagine a computer-controlled machine manipulating a massive block of stone and generating the outcome of a finely skilled sculptor who is holding a chisel in their hand. However, this is exactly what has been accomplished by some companies. Contrary to popular belief, CNC machines are able to easily accommodate slabs as well as cubic stones of any size, however this does rely on the specific equipment that the fabricator opts to use. It’s important to note that not all fabricators with CNC capability have the machine ability to create cubic shapes.

The notion that the CNC method is prohibitively expensive is yet another fallacy concerning this technology. Even though CNC technology is on the cutting edge of advancement, it does not come at a prohibitive price. Throughout history, the production of large-profiled stone parts as well as cubic free-form shapes required a significant amount of human effort. The vast majority of today’s designs start out as digital projects in one of the various computer-aided design (CAD) or digital design tool software products available. When the fabricator works with this “master model” format, it is possible for them to reduce their expenses by a significant amount due to the elimination of the majority of the drawing work that was necessary for the traditional manual technique. In addition, CNC is capable of achieving a very tight tolerance, which eliminates the requirement for additional or subsequent procedures. Fabrication & lead time are also both cut down, while lead costs and costs associated with unique designs are decreased.

Table of Contents

Cost-effectiveness

CNC machines have a reputation for being expensive, which can be intimidating for owners of small businesses who are unsure whether or not the investment would be profitable. The fact of the matter is that because of its high level of efficiency, versatility, precision, as well as ease of use, CNC technology is one of the most cost-effective investments that you have ever made for your company. With Marble Blades you can give the required shapes to the markets while using CNC.

You are able to boost both the quality and quantity of your manufacturing with the help of CNC, which eliminates the need to engage any additional workers. In point of fact, we have worked with a great number of proprietors of small businesses who have discovered that their CNC machine tools may pay for themselves in a period of time significantly less than one year. The computer numerical control (CNC) system has the ability to maximize the usage of workpieces through procedures such as nesting and minimize incorrect cuts, both of which can result in trashed components. This contributes to CNC’s ability to reduce the amount of material wasted.

If you don’t have access to 5-axis machining, you won’t be able to create some components that might otherwise appear impossible. Because of this method, it is possible to mill, bore, then tap a number of different complex forms with just one set up. With merely one configuration, it is possible to generate every conceivable combination of intricate shapes.

If you wish to find the best quality Marble Blades online, then you must find the top supplier online.