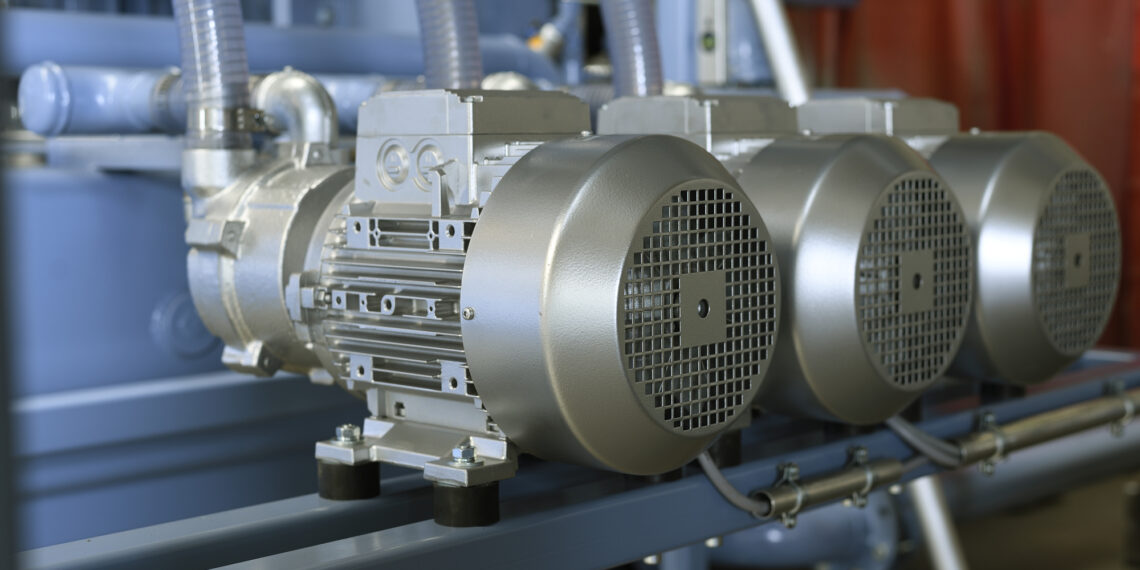

Are you looking for an industrial vacuum pump?

Whether it’s metallurgy or other types of industries, you need this machine. Lacking the proper equipment can cause workplace accidents. However, you might have no idea where to start. There are many vacuum manufacturers out there, and one of the largest is Busch Vacuum Solutions Global.

The good news is our guide can assist your search. Read on as we talk about various types of vacuum pumps. Use these to decide the best machine for your requirements:

Table of Contents

Rotary Vane Vacuum Pumps

These vacuums are the most popular option for automotive and aerospace companies. You can choose from a wide selection of high-capacity models. As such, they can handle various demand levels.

A rotary vane vacuum has varying horsepowers, depending on the specific unit. It ranges from 1.5 to 10. The latter often has a check valve and a direct-drive NEMA motor.

Reciprocating Vacuum Pumps

A reciprocating pump is one of the most dependable types of vacuum pumps. It’s also the oldest, but modern models use various materials. As such, it has a more versatile industrial application.

You will most likely find reciprocating vacuum pumps in the following industries:

- Chemical

- Petrochemical

- Cosmetics

- Pharmaceutical

The best feature of this vacuum pump is its 90% efficient. Its durability is also remarkable, making it the best choice for water jet cutting. As long as it’s about high-pressure, low-flow tasks, you can rely on reciprocating vacuum pumps.

Kinetic Transfer Pumps

These pumps have high-speed blades for directing gas toward the outlet. It uses the principle of momentum transfer to accomplish this task. Meanwhile, some models use introduced vapors instead.

Regardless, these pumps often achieve higher compression ratios. It excels when used at low pressures. However, it typically lacks sealed volumes.

Do you have a vacuum pump in hand? If you need Vacuum Pump Repair & Rebuild, consider clicking the link.

Gas Transfer Pumps

These pumps use either momentum exchange or positive displacement to transfer gas molecules. The pump discharges the same molecules as it enters. When expelled, the gas has above-average atmospheric pressure.

When using gas transfer pumps, their ratio is between the exhaust and lowest pressure.

Dry Claw Vacuum Pumps

Are you in the packaging industry? If so, a dry claw vacuum pump is your best bet due to its efficiency and strength. The following niches also enjoy these features:

- Printing

- Wood processing

- Wastewater management

These pumps offer a high-performance level without excessive noises. The best part is its safety features. After all, they use twin rotors, rotating in opposing circles without direct contact.

Aside from the quality, dry claw vacuum pumps are durable. You can rest easy, knowing they will last for decades.

Discover More Types of Vacuum Pumps Now

These are the most common types of vacuum pumps for industrial settings. Whether you are replacing or buying a new machine, these are the best choices for your business.

However, learning about these is only the beginning. Consider doing more research to get the best brand around.

Did you find this guide helpful? If so, consider reading our other posts today.