Creating a sufficient prototype is essential when it comes to working with your clients. After all, they may not be able to envision how your product will work unless they can see it and use it for themselves.

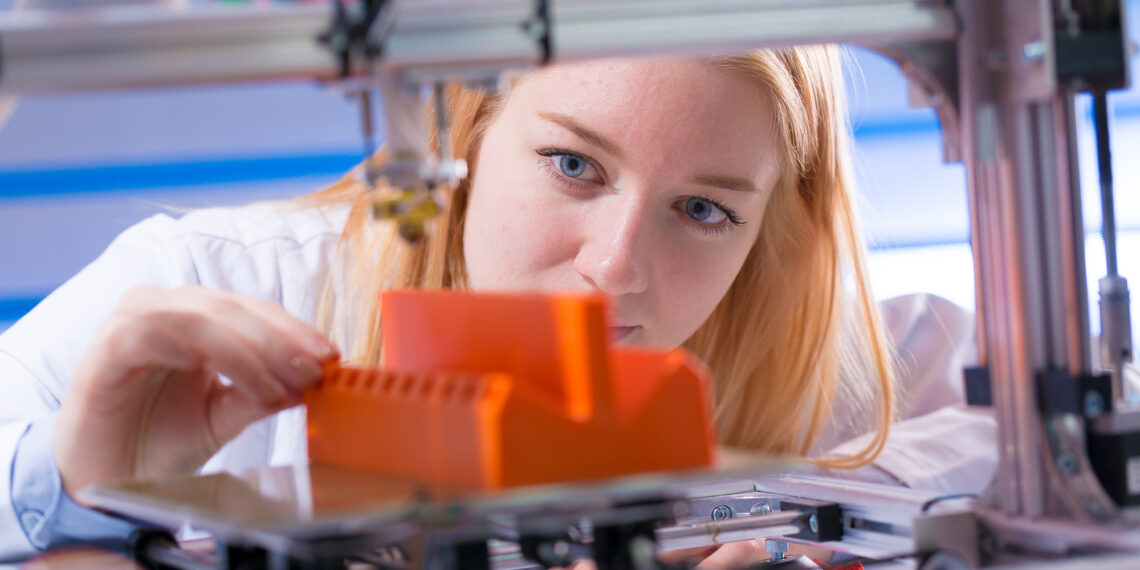

As you might guess, it’s in your best interest to minimize the time you spend creating a prototype. Fortunately, you can use 3D printing for rapid prototyping in order to increase your efficiency.

Let’s take a look at why you should consider this method.

Table of Contents

Minimize the Time to Market

Perhaps the most important attribute of rapid prototyping is minimizing the time to market. After all, it’s always in your best interest to transition from a concept to a deliverable as quickly as possible.

In the past, prototype manufacturing often took months or even years. Today, the process often requires as little as a few days.

3D printing allows you to drastically improve the overall design cycle. So, keep this in mind when moving forward.

Easily Test and Revise

As previously mentioned, it used to take a large amount of time to create a single prototype. This means that revising and testing prototypes was a difficult process.

Since production time has been cut down, it’s often rarely an issue to make revisions to a prototype. The same can be said about any tweaks that need to be made in order to test certain features.

Overall, this leads to a drastic increase in product quality. This is also something that translates into a better brand reputation and high revenue.

Improve Client Communication

Properly communicating with your internal team is always essential. Now that the prototype development process has been simplified through 3D printing, it’s much easier to get everyone on the same page.

This will allow you to avoid a situation where your organization’s upper-level engineers are the only ones who understand the prototype creation process.

For those who want to get involved in leveraging the 3D printing industry for their prototypes, you can check out this service to learn more.

Cost Efficiency

Of course, you can’t neglect the money you are able to save by decreasing production time. This factor becomes even more significant if you develop multiple prototypes at the same time.

With a proper plan in place, it’s possible to scale this endeavor enough so that the mass production of prototypes is feasible.

You can then reinvest the savings into other areas of your production process to become even more efficient.

Rapid Prototyping Is Essential

The longer you take to create prototypes, the less efficient your company will be as a whole. Additionally, you can use rapid prototyping to make multiple prototypes for your clients.

This will give you the greatest chance of getting their approval as fast as possible.

Want to learn more useful info that can help you out in the future? Be sure to check out the rest of our blog.