Nowadays more and more companies are using 3D printing Montreal in order to develop their products. In the past, this technique was most employed to produce prototypes, but this is not really the case anymore at the moment. Instead, businesses even use 3D printing Vancouver to mass produce an object. Unfortunately this does not always go according to plan. During the printing process something might go wrong. These mistakes could also happen before or after the 3D printing has done its job. Below you can find three common 3D printing mistakes you should avoid at all costs.

How does 3D printing work?

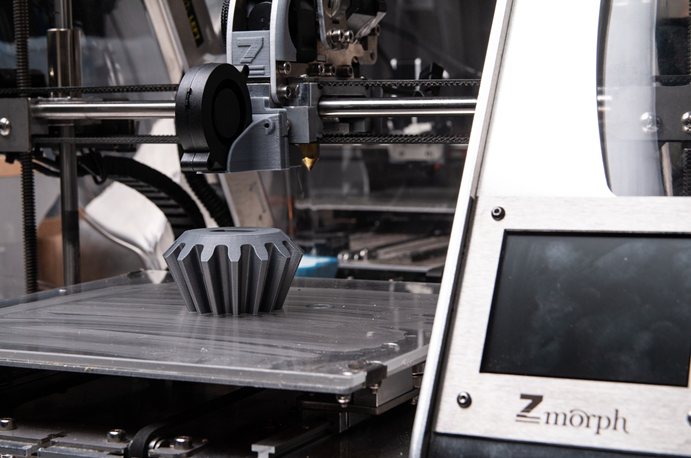

Every 3D printer builds parts based on the same main principle: a digital model is turned into a physical three-dimensional object by adding material a layer at a time. This is where the alternative term Additive Manufacturing comes from.

3D printing is a fundamentally different way of producing parts compared to traditional subtractive (CNC machining) or formative (Injection molding) manufacturing technologies.

In 3D printing, no special tools are required (for example, a cutting tool with certain geometry or a mold). Instead the part is manufactured directly onto the built platform layer-by-layer, which leads to a unique set of benefits and limitation.

Wall thickness

The distance between the two surfaces of a 3D model is called wall thickness. These two surfaces are by the way the front and opposite surface. You need to consider the wall thickness very well. The model obviously needs to be held correctly. In order to achieve this, you need to calculate the minimum wall thickness that makes this possible. This will depend on multiple factors, such as the alignment, size, and overall design. By taking all factors into account you can ensure that the wall thickness is big enough to develop proper, qualitative 3D prints.

Setup

A silly 3D printing mistake that is made quite often is handling the machine without the right setup. Unfortunately this will lead to failed models, which results in a loss of material, while you also essentially waste your time and effort. When you set up the 3D printer before you start the print process, you need to take care of everything to ensure that the process is executed in a smooth way. Nowadays 3D printers are able to do lots of things by themselves. Some of them even let you know when they are out of filaments, but not all machines can do this. Therefore, you need to check it yourself every time before you start printing.

File resolution

Another common mistake that often leads to ruined 3D models is about the file resolution. If this is not correct, the prints may be pixelated. It could also happen that the prints are not very easy to handle while they are being printed. File resolution is therefore an important aspect. It essentially describes the accuracy and smoothness of your file. All 3D printing machines have lower and higher resolution capabilities. If your file resolution falls between these two numbers, this might lead to a bad print.