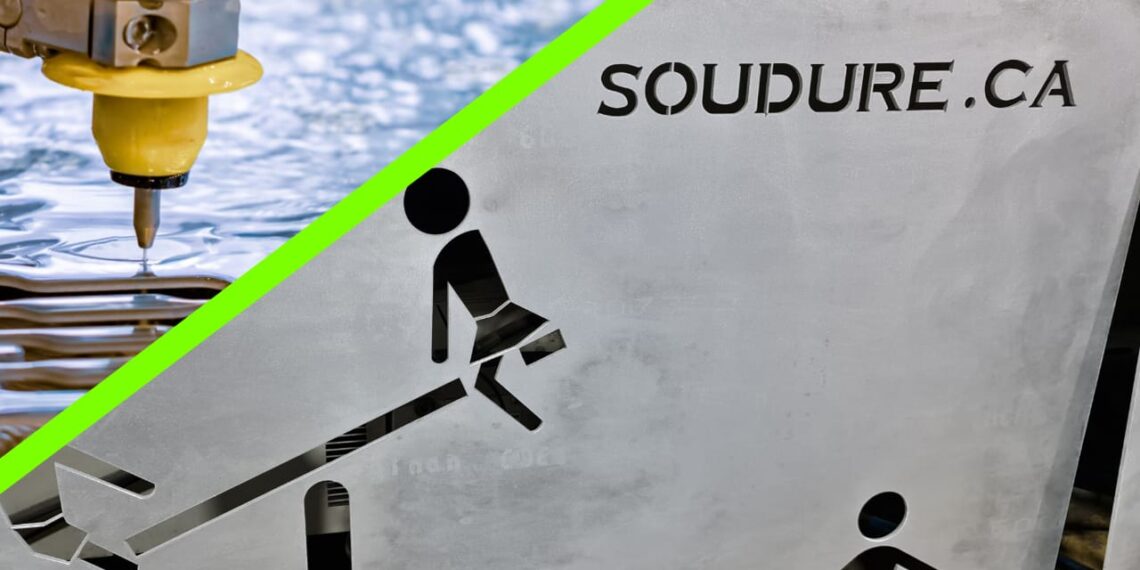

In the industrial setting, waterjet cutting is a technique that utilizes high-pressure waterjets to cut through various materials.

A waterjet cutting device can be used to cut most types of materials. Metals, stone, cardboard, paper, rubber, plastic, composite materials, and food are a few of the materials that could be cut using a waterjet machine. In order to increase the cutting force for complex materials, an abrasive is added to the process of waterjet cutting.

With experts from Montreal-based Taylor Steel & Stainless, we talked about the benefits of making use of the waterjet cutting for each of these materials, as well as exactly how to cut every single one of them:

Metal

Waterjet devices can cut through all kinds of metals. Along with several other metals, such machines can cut through aluminum, brass, steel, and copper. These machines make use of the cold-cutting process.

The cold-cutting procedure removes heat zones that develop as a result of mechanical attributes and chemical reactions present inside the product. It is advised to cut metal components that have been immersed in water to lessen safety risks in your workspace.

During the waterjet cutting process, certain materials, like dust particles, broken pieces of metal, and filaments, get caught inside the water. Alongside benefits and safety precautions, waterjet is recommended for cutting through metal due to its effectiveness.

Glass

If you don’t have the appropriate equipment, cutting glass can be among the most tedious tasks. Due to the requirement for a tool change at nearly every stage of cutting and the fact that glass is a sensitive material, it could be extremely time-consuming and expensive.

But there is no need to panic; cold water cutting processes could produce the desired design while cutting through glass with great care and precision.

For the numerous waterjet cutting machines present, as was already noted, there are pre-programmed designs. Top-quality and accurate glass products are made possible by these designs.

Stone

Waterjet cutting devices can slice through both natural and artificial stones. Every other conventional method of cutting stone is surpassed by the mechanics found in waterjet cutting machines.

Using drills, saws, and milling cutters, among other conventional stone-cutting methods, is usually time-consuming and costly. For this reason, the preferred method for cutting through stone is waterjet cutting.

Composite Material

One type of composite material is fiberglass. These materials can be identified by their delicate nature and lightweight. Because of this, cutting can be challenging, particularly while using the wrong cutting equipment. Therefore, the best cutting technique for materials like these is abrasive waterjet cutting.

The ultimate product is guaranteed to be flawless thanks to the waterjet cutting process. From the start of the process of cutting till it ends, it is accurate, quick, and maintains the integrity of the fiberglass.