The manufacturing industry is constantly evolving, and the 3D printer could be the next leap.

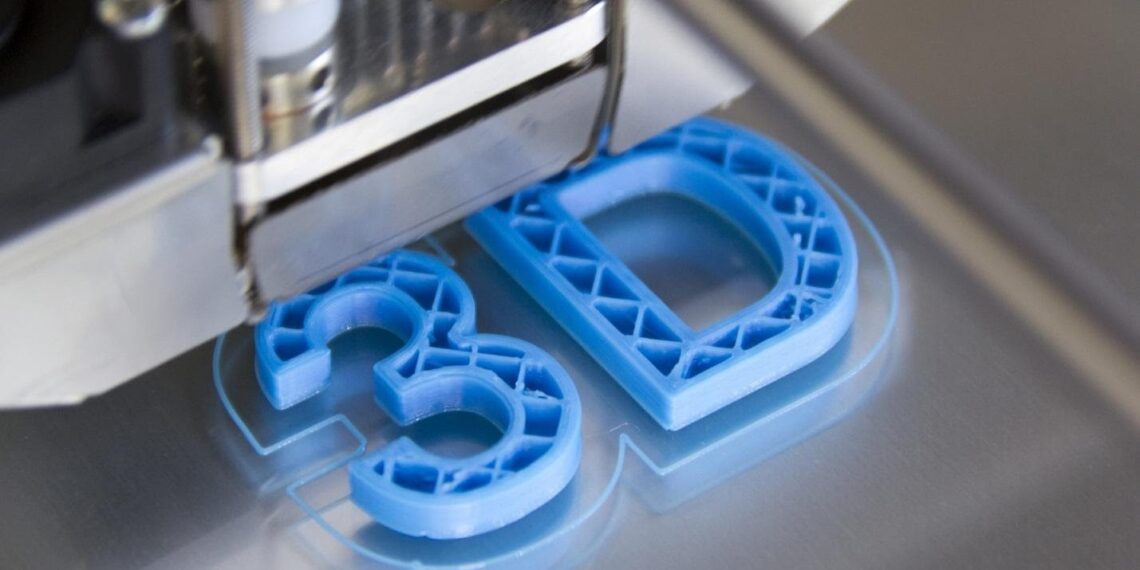

3D printing, also known as additive manufacturing, is the method that permits a three-dimensional tangible object to be produced from a digital image. When 3D printing was first made available, it was more of an artifact than a valuable tool for creating unique trinkets and other souvenirs. Thanks to less expense and technological advancements, 3D printing is now within many people’s reach, and 3d printers are available online. It is already being used in various fascinating ways, ranging from medicinal applications to shoe manufacturing.

Like all modern technological breakthroughs, there are advantages and drawbacks. This article will examine the implications and discuss the state of 3D printing and where it could be heading.

Table of Contents

The current situation

The market for 3D printing has been growing steadily throughout the years. The primary market, which includes 3D printing machines, printing materials, equipment, and services, has been growing at least 30 % every year between 2012 and 2014, as per the report released in 2014 by both the Consumer Technology Association (CTA) as well as the United Parcel Service (UPS).

The report, entitled “3D Printing: The Next Revolution in Industrial Manufacturing,” discovered that two-thirds of manufacturing companies already utilize 3D printing at least in one manner and that 25 percent were planning to use this technology shortly. Companies cited prototyping design, product development, and innovation as their primary motives for using 3D printing.

The automotive and consumer electronics industries account for 20% of total 3D printing earnings, using the technology mainly in the prototyping stage of production, per the report issued in the CTA and UPS. However, some companies are expanding beyond prototyping. For example, smartphone makers have begun to use 3D printing for certain parts of their devices.

The medical sector is the third-largest 3D printing industry, accounting for 15% of total 3D printing revenues. The medical industry uses the technology to produce mass-customized products, like hearing aids, and 98 % of all hearing aids globally are manufactured with 3D printing.

However, 3D printing has not replaced a large portion of the manufacturing industry as less than one percent of the production output is 3D printed.

Arguments for and the Against

Presently, 3D printing is most often used to create prototypes since changes are generally more straightforward and less expensive to develop when compared to the need to reset factory machines. This technology is perfect for production with low volumes, for example, craft products such as jewelry or custom-made products such as prosthetics. Dental crowns and hearing aids are being produced by millions using 3D printers.

It’s also ideal for creating intricate and lightweight forms for high-value items ranging from race cars to aircraft. This is because the printer puts materials only where they are needed. GE has already invested $1.5 billion in this technology to produce jet engine components, among other things.

However, some think 3D printing is unlikely to become a mainstream feature in the manufacturing industry because it is incredibly time-consuming. Some complicated items can take up to two days to design. Currently, the price of the equipment and materials used for 3D printing can be high, and the variety of materials is a tiny fraction of the materials employed in conventional techniques.

In the keynote address during the Canadian Manufacturing Technology Show, Kirk Rogers, technology lead at the GE Center for Additive Technology in Pittsburgh, warned that additive manufacturing could not completely replace traditional manufacturing. According to him, of the components GE creates at additive manufacturing facilities, 85 percent have needed conventional manufacturing techniques, such as machine tools.

What do we think the future holds for us?

Although 3D printing might not yet be taking control of the whole manufacturing sector, experts predict it will see significant growth, and the market could be worth 32.78 billion dollars in 2023.

Several manufacturers have already begun to look into the market to discover what opportunities are available. Adidas, for example, has been using 3D printing, a process known as “digital light synthesis,” to create the soles of shoes by pulling them in fully formed from a liquid polymer. The method is being used in a few newly-built Adidas manufacturing facilities within Germany and America to make one million pairs of footwear each year, which will be available for sale faster than traditional processes allow.

The cost of printing with metal could be altered through 3D printing, using a new technique known as a bound-metal deposition. The method can create objects at a rate of over 500 cubic centimeters per hour, compared to just one or two cubic inches per hour with a standard metallic printer that is laser-based.

The full implications of 3D printing for manufacturing are difficult to anticipate. However, based on the events that have occurred so far in the field and what the analysts expect to see over the following years, it’s plausible to conclude that we’ve not seen 3D printing employed to its fullest potential.

If you are interested in buying 3d printers and 3d printing resin, you can visit hydro tech 3d Chennai’s official website? Whare you can explore affordable 3d printers like phrozen Sonic Mini 8k.