Supply chain management is one of the biggest priorities for most small and mid-size business owners looking to expand their operations. The ultimate goal of improving supply chain efficiency is to minimize wasted space on warehouses, inventories, and store shelves.

In general, organizations use various tools and techniques to manage their operations and activities. Syncing and monitoring these systems simultaneously can be a hurdle and may reduce an organization’s ability to respond to complex business requirements.

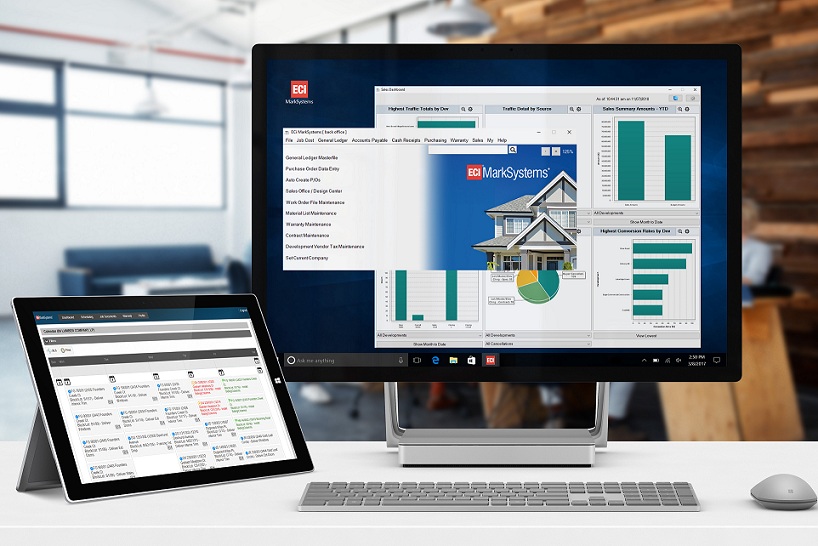

The best ERP software Solution turns out to be a natural fit for the increasing demand for the supply chain. It incorporates, accommodates, and automates all business components, thereby enhancing the effectiveness and efficiency of the supply chain.

Let’s take a look at how ERP software can improve a company’s supply chain management.

Table of Contents

Standardized process and information

ERP software centralizes the data of an organization across all its systems and locations. Businesses transitioning from small to midsize operations can find themselves in a hurdle where data is not being effectively shared across all organizational departments. This mismanagement of information can adversely affect the supply chain by posing various efficiency and security-related threats.

When we talk about the supply chain, moving information about a product/service from one point to the other without being tampered is as crucial as the movement of the product itself. ERP manufacturing software standardizes data across the organization and mitigates time and resources lost over miscommunications. Therefore, it keeps the process consistent by having all the data in one system, thereby automating more of the supply chain functionality and reducing the time and efforts required by humans to keep things working.

Accurate planning with IoT

Manual inventory management reduced real-time visibility into the inventory. Suppliers and retailers would not be able to track their most-selling products going out of stock, which will make your customers unhappy. Thus, having an accurate count of stocks is critical.

The Internet of Things (IoT) technology helps you overcome this hurdle. Suppliers can use IoT-enabled RFIF tagging and sensor-based tools that offer an effortless way to collect and transfer information to your ERP software.

Greater transparency

Silo mentality can affect the supply chain, but that does not mean you need to take away access to data from people who need it. Instead, provide them with accurate, updated, and relevant data. Not only you, but your employees, too, should have access to relevant supply chain data, like the amount, location, and expected delivery time of the product in transit. All members across your organization should see numbers that are consistent and accurate.

ERP manufacturing software provides a comprehensive, centralized view of the supply chain, which allows you to make intelligent decisions around ordering, customers, and promotions. Plus, it gives a detailed oversight into the supply chain, enabling you to identify, understand, and overcome issues more quickly and effectively.

Enhanced decision making with Business Intelligence capabilities

As discussed before, ERP software offers greater transparency into the supply chain, which improves the decision-making process. However, it’s not just access to data that you get. Modern-day ERP systems entail Business Intelligence capabilities that turn the captured data into actionable insights for enhanced reporting, analysis, and panning.

The information generated expedites seamless monitoring of business activities, which allows you to recognize disruptions before they affect your operations. In addition, it also improves collaboration between stakeholders, helps you assess the performance of vendors, lowers operational costs, and improves the overall supply chain efficiency.

Effective handling of increasing customization

The rapid advancements in technology have resulted in the supply and retail world evolving fast, with consumers being more empowered than ever before. They expect more flexibility in how they can make purchases, which has led to a shift towards increased levels of mass customization. This has created new challenges like short cycle times and complex assortments.

The latest ERP manufacturing software can store and organize a copious amount of data using tables and matrices to help you manage the buying and selling of products featuring any type of level of quantitative customization. To cope up with these varying demands of consumers, supply chain companies require an ERP system that can accommodate these mishmashes and comply with the omnichannel retail model to distribute the product.

The use of cloud computing

Most ERP software programs nowadays come with cloud capabilities. Cloud technology enables you to establish and access an interconnected system that provides an exhaustive view of all the operations that can affect the growth and efficiency of a supply chain business.

The adoption of cloud computing has also enabled companies to cut down the hassle of updating and maintaining on-premise programs, which results in substantial savings through the everchanging supply chain business landscape.

Final thoughts

The evolving dynamics of the supply chain have increased the need for control, transparency, and standardization across operations. Supply chain organizations need significant developments in their network performance to achieve better supply chain management efficiencies and tangible ROI.

A robust ERP manufacturing software can go a long way in maximizing the organizational effectiveness of a business. Modern-day ERP software is powered by state-of-the-art tools and technologies that make supply chain organizations more flexible to change, along with making them more proactive in responding to the changing dynamics.