Weighbridges, also known as truck scales or weigh stations, play a vital role in accurately measuring vehicle and cargo weight. As a result, their most prominent application is in logistics, transportation, mining, and agriculture, where precise weight measurements are essential for compliance, safety, and operational efficiency.

So, how many varieties of weighbridges exist? Read on to find out.

- Pit Weighbridges

Pit weighbridge installation is in a pit or recessed area, allowing the weighing platform to be at the same level as the ground. This design provides a smooth and seamless surface for vehicles to drive onto the scale. Pit weighbridges offer several advantages, including effortless vehicle access, minimal ramp space requirements, and enhanced stability due to the lower centre of gravity. However, they require excavation work during installation, which can increase costs and time.

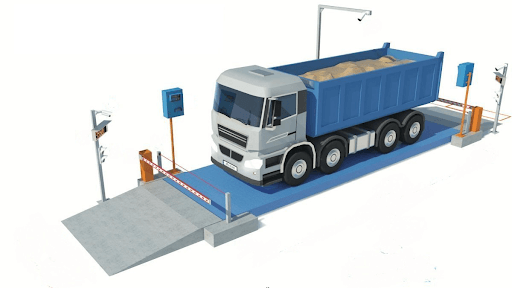

- Surface-Mounted Weighbridges

These weighbridges have an above-ground installation. Construction of these weighbridges includes ramps on both ends, allowing vehicles to drive onto the platform. Moreover, they are relatively more straightforward and quicker to install than pit weighbridges, making them a popular choice in temporary installations or sites where excavation is not feasible. In addition, surface-mounted weighbridges are versatile and permit easy relocation if required.

- Steel Weighbridges

Steel weighbridge construction uses steel beams and plates, making them sturdy and durable. As a result, they can handle heavy loads and provide excellent accuracy in weight measurements. This property makes steel weighbridges the preference in industrial applications where robustness and reliability are crucial. Additionally, steel weighbridges offer resistance to corrosion, ensuring long-term functionality even in harsh environments.

- Concrete Weighbridges

Concrete weighbridges are built using reinforced concrete slabs and beams. They are renowned for their strength, durability and resistance to wear and tear. Concrete weighbridges can withstand heavy loads and frequent use, making them suitable for high-traffic areas. While the installation cost may be higher than other types, these weighbridges require minimal maintenance and offer a long service life.

- Portable Weighbridges

Portable weighbridges are easily transported and set up at different locations. Their construction typically entails lightweight materials such as aluminium or steel and features modular components. Portable weighbridges are ideal for temporary installations, construction sites, or agricultural operations where mobility is essential. Their easy assemblage and disassembly allow for convenient relocation and cost-effective use.

- Axle Weighbridges

Axle weighbridges, also known as axle scales or axle pads, are specialised weighbridges designed to measure the weight of individual vehicle axles or wheels. They are compact, portable, and easy to use. Typical axle weighbridge use includes weight enforcement, load distribution analysis, and vehicle safety inspections. Furthermore, they provide valuable information about axle load distribution, ensuring compliance with legal weight limits and preventing damage to roads and infrastructure.

Table of Contents

Conclusion

Weighbridges are indispensable tools for accurate weight measurement in various industries. Whether for compliance, logistics optimisation, or safety considerations, choosing the right type of weighbridge is essential. Understanding the different types of weighbridges empowers you to select the most suitable option based on your specific needs, ensuring efficient operations and reliable weight measurement.