What should we keep in mind while buying an entry-level 3D printer? Under the price range of there is not much room to choose, but still, there are few particulars that are feasible to favour or to count.

Table of Contents

Buying guide For 3D Printers

Technology:

At the present time, the only technology that is accessible is extrusion (FFF/FDM) 3D printing. Some adhesive SLA (Polymerization) 3D printers are being manufactures or developed, but they are still at the pattern phases. Although this is not certainly a bad thing, as FFFF/FDM technology is less tangled than other classifications. Some adhesive 3D printers are more transformed for dental and jewellery applications.

If we talk about print quality then this is mainly dependent upon layer thickness and XY resolution; with our differentiation engine, it is practicable to contrast these characteristics or features side-by-side for the variety of printers. To learn more about these different 3D printing technologies and processes, I will tell you about some of these printers.

DIY kits versus assembled 3D printers:

Most of these 3D printers are DIY at a very low-price range, which means they are carried out in unassembled kits, much like a well-known Swedish brand’s furniture. Even after it is perfectly assembled we think it is totally ready to use and there would not be a single defect but still there is a probability that 3D printers will not function well. Just one loose screw can produce messy or grubby prints. So, it is very important to keep relax and do not get aggressive on this printer.

DIY 3D printer kits can effortlessly be enhanced by 3D printing extra sections. 3D printers’ kits are very easy to learn how it works but it may cause a little problem and discourage for freshers. Also, there are few 3D printers that are pre-assembled in this list for people who are not afraid of technicalities.

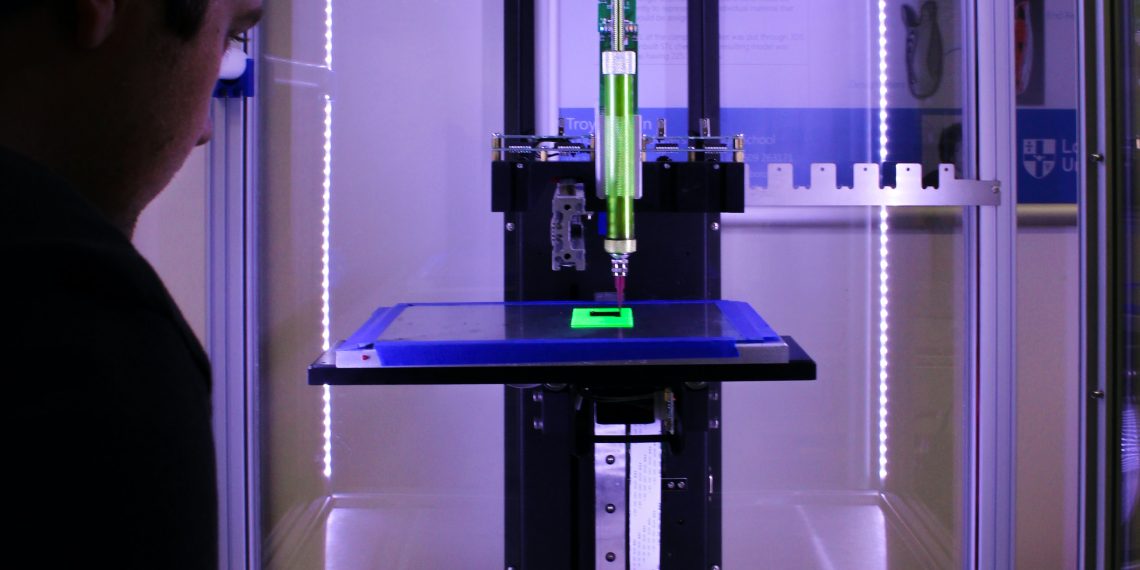

Closed frame versus open frame:

You must learn to manageable 3D printers to get effective 3D prints, specifically with open-mounted machines. With 3d print quality, many things may restrain such as temperatures and room drafts. For basic security, it is workable to add temporary “walls” with cardboard, for example around an open-mounted 3D printer. Closed framed 3D printers secure the printing process, protects from smelly fumes like the smell of melted plastic, and help mask the 3D printer’s mechanism noises.

Community Support:

As you know, if the prices of 3D printers are low then the sold printers’ range becomes higher and usually leads to large active user communities. Though it could be a good thing and a bad thing also. So, there is a con about this printer that sometimes manufacturers cannot handle is after-sales customer requests, so it is very important to notice to check their websites and views to get a foretaste. On a less, serious note if a certain model or kit has enough users or customers on specialized forums or websites then they can get help and frequently asked questions wizard.

There is a list of the best general 3DP communities that have immense information or material for many 3D printers. Information about a specific model or kit can be found with a quick search engine query.

Build Volume:

Another important feature or spec to consider the 3D printer is build volume or maximum size of a 3D print. If you just want to experiment and discover 3D printing then you will not be able to understand the importance of build volume; it won’t be too significant, unlike if you want to print specific parts with certain measurements. You can also go for the large build size volume.

Automatic calibration:

The accuracy of 3D print can easily be deceived if the print bed is microscopic unsymmetrical. Some of the 3D printers present automate bed levelling, but a lot of others requires manual adjustments. Doing it manually is quite challenging and time-consuming but it gets better with practice and then it becomes a habit but it makes sure that bed is perfectly levelled.