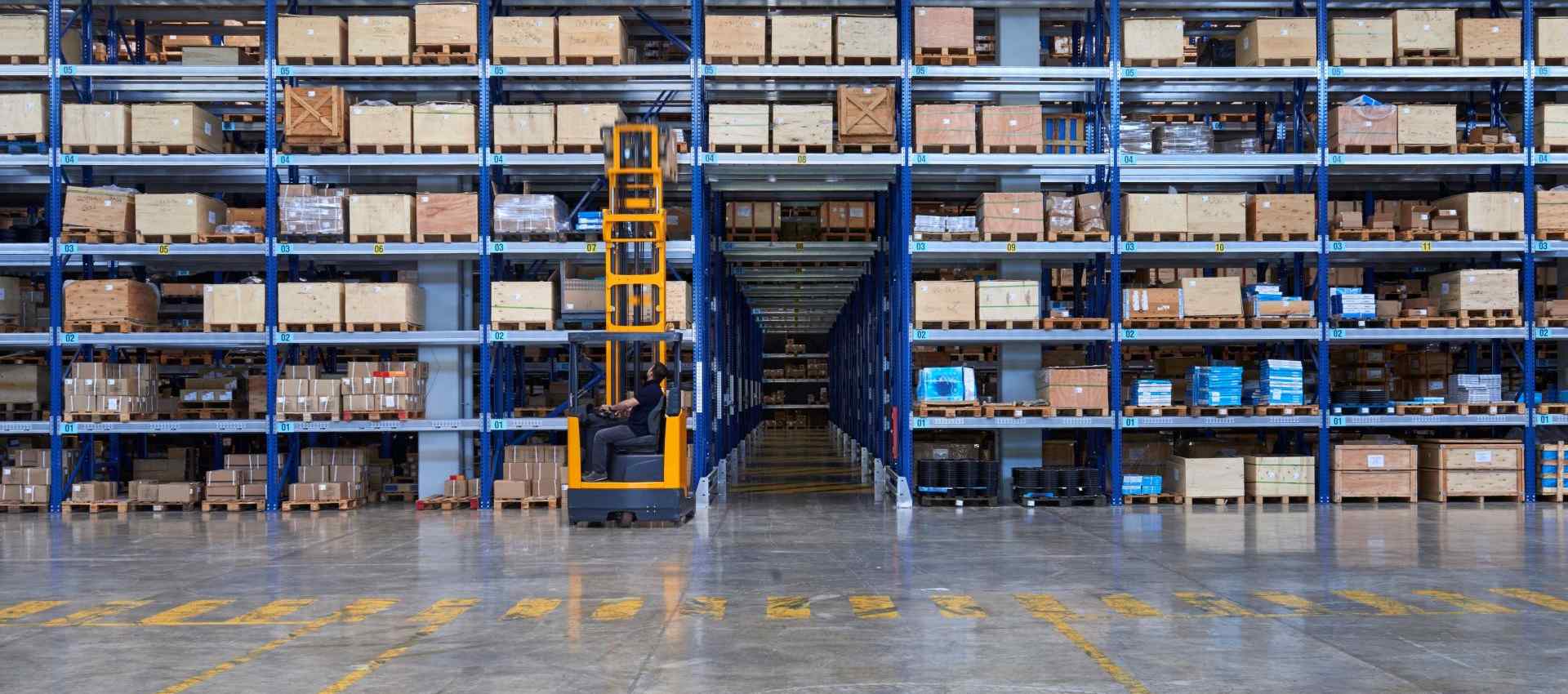

When making an investment decision for your business or company, it’s essential to consider the different options available and the factors that can affect the decision. For instance, an industrial shelving system is critical to successfully managing your warehouse. It provides an easy and cost-effective way of storing large volumes of goods. Thus, choosing the right shelves boosts the safety of your items and helps increase productivity through better space organization.

Investing in an industrial shelving system has many benefits. They’re durable and can support heavy goods, and are convenient as they allow easy access to goods and help reduce clutter through space optimization. These benefits boost productivity at a low cost. However, choosing the right industrial shelving products that fit your needs can be a hassle. Luckily, we’ll outline the various factors to consider to make the process smooth and successful.

Table of Contents

1. Budget

In choosing the right industrial shelving solution, participants need to consider the items to be stored, their size and weight, how often they’ll be accessed, and how much the budget is. Besides, don’t make a rushed decision because something is cheaper and you can afford it. Instead, look for an affordable shelving system that suits all your needs. Sometimes, cheaper shelving systems may not be the best as they aren’t adaptable and versatile enough to changes. Additionally, expensive doesn’t always guarantee high quality, so take time to review the different options and settle for a commercial shelving solution that’s affordable and adaptable to your operational needs.

2. Safety Regulations

When investing in industrial shelving, it’s essential to consider the safety issues and how they can impact your investment decision. The government stipulates laws and regulations to ensure that industrial shelving systems are made with government standards, correct materials, and suitable for the required storage. So, before settling for a shelving product, ensure it abides with the local safety laws and regulations to avoid unnecessary costly issues.

For example, industrial shelving products made from plastic, glass, or wood can’t pass fire regulations, while those made from lightweight and galvanized steel pass all the building laws and safety codes.

3. Floor Plan And Layout Of Your Warehouse

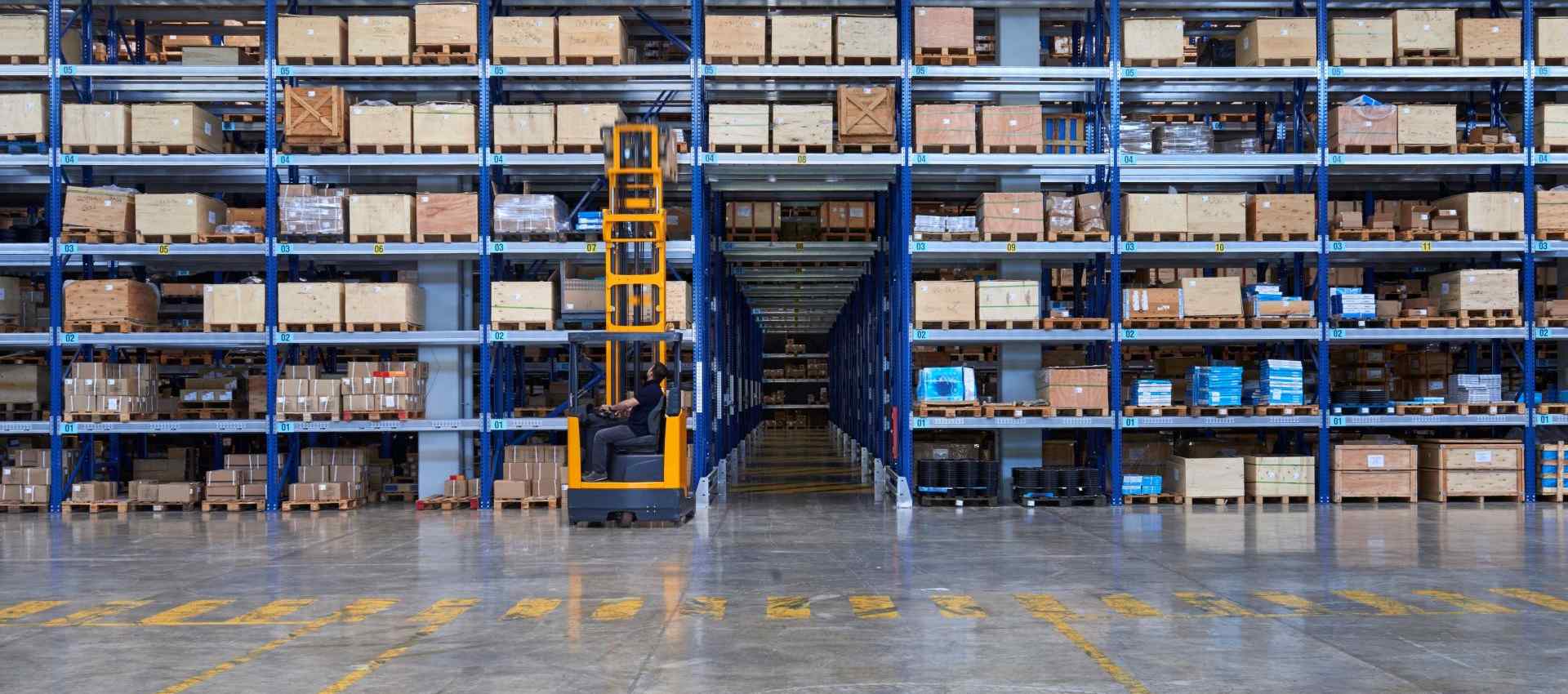

Your industrial warehouse can be in different shapes and sizes. Thus, it’s crucial to map the area, its dimensions, and all the access points, including the windows and doors. Familiarizing yourself with your warehouse layout helps identify which shelving products to use. If analyzing your warehouse is challenging, you can hire a warehouse specialist to help you with the type of shelving products to use so they would perfectly fit the warehouse to optimize the space and increase functionality.

Aside from the floor plan and general layout, the warehouse specialist will also consider the warehouse’s vertical space to help design a shelving system that will utilize all the available space. Using your vertical space in full significantly increases your storage capacity by even double. However, consider other linked costs when utilizing your vertical space, like lifting equipment and crane.

4. Access Needed

When selecting your industrial shelving solution, you should also consider how frequently your goods need to be accessed. Goods that require frequent access should be shelved differently than those that are accessed occasionally. Moreover, consider how cranes and lifting equipment can access the goods. Choose shelving products that will leave enough space for lifting equipment to move around the warehouse easily.

5. Future Use

When choosing an industrial shelving solution to invest in, avoid focusing on your current needs only; instead, look at your future needs and development plans. If your industry has room for growth or is likely to change, you must invest in versatile shelving solutions that can change and grow alongside your firm. If you fail to do this, you may invest in shelving products that will need to be changed again after a few years, which can be expensive in the long run.

6. Maintenance Cost

Once your shelving products are installed, they need to be maintained regularly. Before settling for a shelving solution, it’s vital to consider the ease of maintenance. Choose a shelving solution where spare parts are readily available and experts are within reach to conduct necessary maintenance and repairs. Generally, your industrial shelving provider should be able to provide ongoing support and maintenance services for seamless operations in your warehouse.

Conclusion

This article has listed some things to consider before investing in a shelving solution. The information you gain here should answer your questions and help you choose the best shelving solution that meets your needs