Did you know that over 2.6 million non-fatal work injuries occur in the United States each year?

They occur for several reasons, one of which is unsafe work environments.

Whether you are a warehouse worker, part of a warehouse management team, or own a warehouse, you need to ensure that your operation is as safe as possible.

Read on to learn what safe warehouse operations look like and how you can install them into your daily operation.

Table of Contents

1. Clean and Well-Organized

A clean and well-organized warehouse is a safe warehouse. This means sweeping and mopping the floors, cleaning the shelves and racks, and organizing the inventory.

A clean and well-organized warehouse is easier to navigate and helps prevent accidents.

2. Training Safety Procedures

You should train your employees on safety procedures before allowing them to work. This will ensure that they know how to operate in your warehouse and will help prevent accidents.

Some of the best practices for training your employees on safety procedures include the following:

- Providing them with an employee safety manual that outlines all the warehouse’s safety procedures

- Going over the safety procedures with them in a meeting

- Making sure they understand and can follow the safety hazard procedures

- Providing them with personal protective equipment (PPE)

- Conducting regular warehouse safety audits and training sessions

- Certifying that your employees are up-to-date on all safety procedures

3. Regularly Inspecting

Regularly inspecting the warehouse for safety hazards is one of the best practices for safe warehouse operations. By identifying and addressing potential safety hazards, you can reduce the risk of workplace injuries.

A thorough inspection of the facility should be conducted regularly, and any potential hazards should be remedied.

4. Ventilation and Cooling

One of the most important practices is to ensure that products are stored at the correct temperature.

Ensure that your warehouse is sufficiently ventilated. Poor ventilation can lead to the build-up of dangerous fumes and vapors, which can harm both employees and stored products.

Make sure that ventilation fans are properly installed and maintained. To be effective, ventilation fans must be able to move air throughout the warehouse.

Ensure that your warehouse is cool. Storing products in a cool environment can prolong their shelf life and prevent spoilage.

Consider installing a cooling system like this product, if needed. A cooling system can help maintain optimal storage conditions for products sensitive to heat.

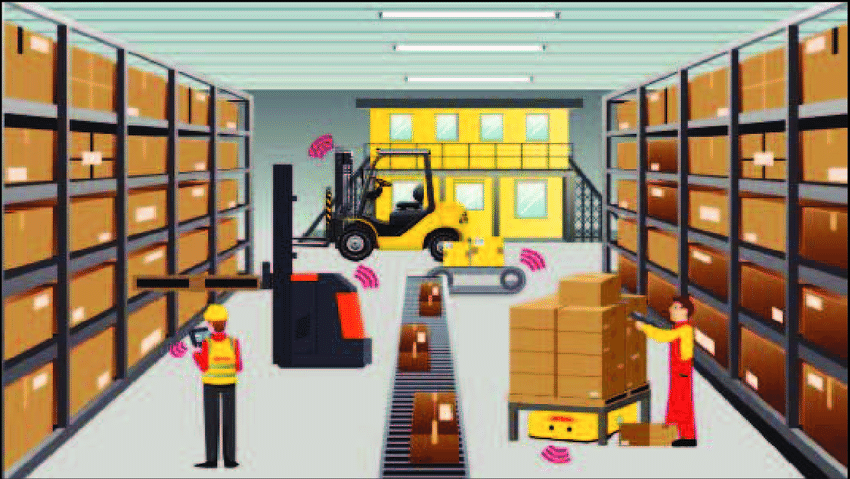

5. Latest Warehouse Technologies

The latest warehouse technologies can help operators to improve safety and efficiency in their facilities. By investing in new equipment and systems, operators can reduce errors and improve communication between workers. Additionally, well-designed warehouses can help to eliminate potential hazards.

Efficient Warehouse Operations

To ensure safe and efficient warehouse operations, it is significant to follow best practices. With these best practices, warehouse operators can create a safe environment for their employees. Help prevent accidents and injuries.

If you’re interested in learning more. Check out some of our other articles on the subject.