HVLS stands for high-volume, low-speed fans that distribute huge amounts of air at a reduced speed. The benefits of HVLS fans have been proven time and time again. Here are 5 of the most significant reasons to install an HVLS fan in your operation.

Table of Contents

1. Energy and Cost Savings

According to the American Society of Heating, Refrigerating and Air Conditioning Engineers (ASHRAE), there is a five-year return on investment on installation and operation of HVLS fans. A 49% energy savings was found in Minneapolis, MN plus a substantial decrease in the generation of CO2 and carbon. Best suited for large open spaces with a minimum ceiling height of 15 feet, HVLS fans are the most energy-efficient air circulating fans on the market.

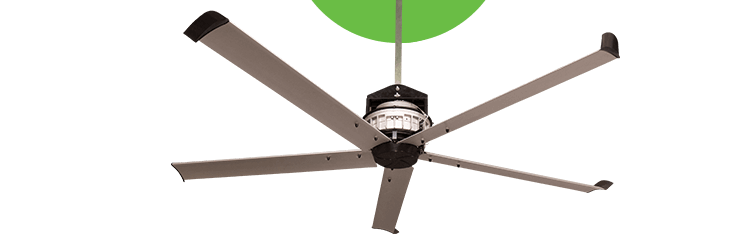

2. Italian Design and Engineering

There is a specific aerodynamic design of the fan blade that causes an increased airflow. Italian engineering is credited for creating a high-quality form of displacement of air through technology. In warm weather and cold weather, the physics in the reverse rotation makes it suitable all year round.

3. Diversified Industries

From banquet rooms to cattle barns, HVLS fans are used for increased ventilation. They help circulate trapped heat near the ceiling, forcing it down to circulate without a windy effect. Here are a few examples where HVLS fans are beneficial:

- Operations that produce smoke or fumes

- Warehouses with no air-conditioning

- Buildings that have large open doors

- Commercial bakeries where the dehydrating effect of air-conditioning is undesirable

4. Comfortable Temperatures

Slow-moving air will add 10-15 degrees for heating or cooling to make buildings more comfortable. Better air mixing delivers better air quality. HVLS fans are virtually void of noise, causing no disruption from noisy blowers. Studies show that cattle are less stressed under the large air-circulation and have a positive effect on milk production.

5. Contributes to the Green Building Movement

Without a lot of fancy equipment or high prices, HVLS fans are a green building alternative. HVLS fans cost approximately $4000-$5000 each, including installation. This money is recovered in a few short years. Existing wiring can often carry the amperage needed for these fans and manufacturers claim that an average fan will last 10 years.

HVLS fans are simple, straight-forward, and quality designed and built. Large ceiling fans in hot climates have appreciated the concept of slowly moving air. Faster is not always better as shown by the dramatic benefits of the HVLS fan.