If you’ve spent any amount of time in new product development for your business, then you know just how much time it takes for your idea to become a reality. Depending on the manufacturing process and the complexity of your product, it can take at least a year to get it to market.

What if there was a way to speed up that process? With rapid prototyping there is! Read on to learn all about the undeniable advantages of rapid prototyping in the manufacturing process!

Table of Contents

Perfect Your Designs

Product manufacturing is all about trial and error, especially when you’re just getting started. There are a number of different ways you can design your product, but which one will work the best for you?

If you don’t like the prototype that comes out at the end of your manufacturing process, then you have to start all over again. Not only does this slow down your development process, but it also drives up costs.

Rapid prototyping allows you to create different variations within a particular design to allow you to test out a number of options all at once. Traditional CNC machining and sheet metal fabrication just aren’t capable of this. You’ll know that when your product hits the market, it’ll be the best version.

Mitigate Your Risks

Perfection isn’t always possible, but you can get pretty close to it with rapid prototyping.

Creating several different versions of your prototype helps you identify and correct issues with your product long before you hit the market. This means you don’t have to worry about going back to the drawing board after you’ve spent tens of thousands of dollars (or more) creating your product and getting it on the market.

Get Your Products to Market ASAP

One of the biggest advantages of rapid prototyping is found in its name — it helps you get a product to market much faster than you otherwise would if you went through a traditional product manufacturing process.

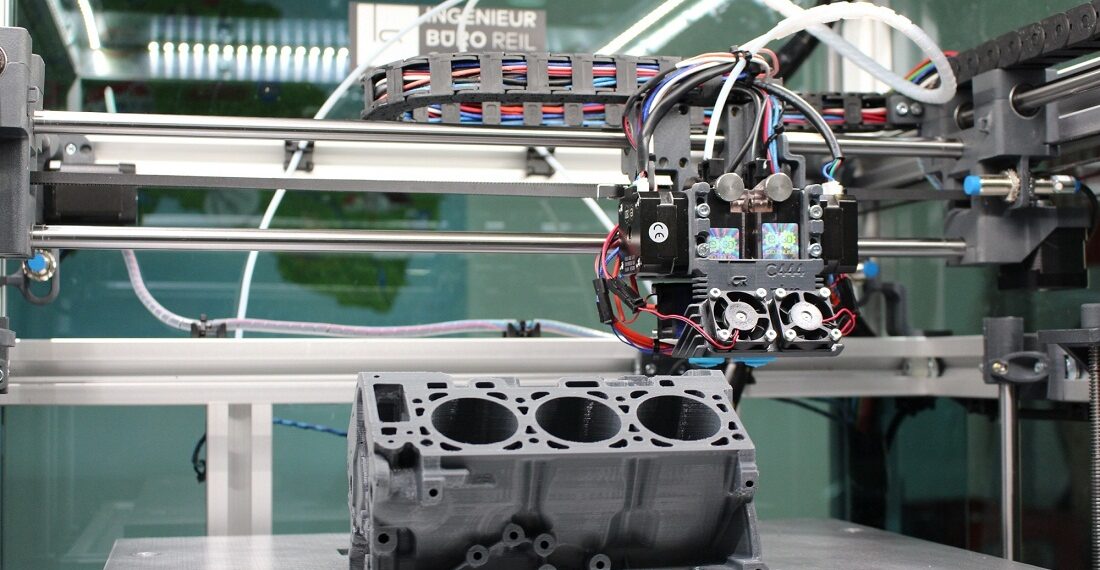

With rapid prototyping, simple products can be manufactured using 3D printing technology in just a few hours. 3D printing uses a CAD model and prints directly from the file without requiring the setup of other machines, which is what typically causes production lags.

Small parts under 4 inches in diameter only take four hours to print, while larger ones may take up to 20 hours. If you don’t have 3D printing equipment on hand, contact Techcraft3d.com to learn how quickly you can get prototypes delivered to your business.

Make Rapid Prototyping Part of Your Manufacturing Process!

They say good things come to those who wait, but those people have obviously never had to deal with the stress of product prototypes. By switching to rapid prototyping, you’re not just saving time, but you’re also getting the opportunity to explore all of your options to create the best product possible. There’s nothing not to like about it!

Are you looking for more great ways to improve your new product development process? We can help you with that. Scroll through the rest of our blog for tons of great tips that’ll keep you ahead of the game.