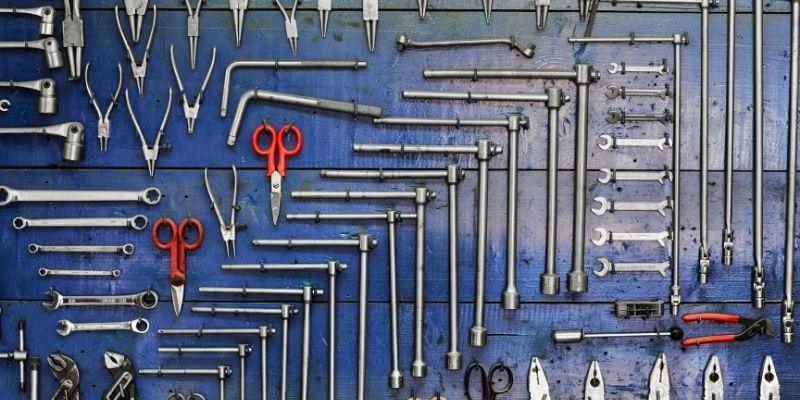

Precision tools are a must-have in the construction and any goods-producing industries because they help with quality control. In addition, hand tools increase efficiency by saving time by reducing the need for manual measurements. Consequently, using such tools saves costs as they reduce waste and errors, saving the company’s resources. However, getting the right precision tools to benefit from them would be best. Here are the five features you must consider to choose the right precision tool.

- Accuracy

Accuracy is a crucial feature to consider when choosing tools for inspection, such as calipers, scales, steel rulers, ring gauges, and indicators. Inaccuracy in these hand tools can cost you due to errors. To ensure accuracy, you will check the calibration by ensuring the tool is easy to calibrate. It’d be best if the tool provided detailed specifications like resolution and range of measurements. Brand reputation and reviews can also help you to determine accuracy. But for certainty, check if the tool meets the National Institute of Standards and Technology (NIST) standards.

- Ease of Use

This feature is essential for frequent use and accuracy. The tool should be intuitive to enable the inexperienced to use it. It should also come with an ergonomic design for comfortable handling. Its user interface should be simple to reduce the chances of errors. The more versatile, the better, because you won’t need to switch between different tools. You will look for a quality brand and check the specifications to get such a tool.

- Compatibility

It’d be best also to check compatibility when choosing precision tools to avoid problems such as downtime and the need for additional ones. The tool should be compatible with the software or equipment your company uses. You will learn about the compatibility by checking the tool’s specifications and whether it’s designed to work with software such as Computer-Aided Manufacturing (CAM) or Computer-Aided Design (CAD). Contacting the manufacturer about the same would also be best, especially if it doesn’t mention compatibility in the product description.

- Portability

Portability is another crucial feature because you must carry the tool. A portable tool will be easy to handle and flexible, ensuring optimum use. Additionally, a portable precision tool offers convenience because you can use it in different environments regardless of the project’s complexity. Such a tool will also save your company from buying more of the same. To determine portability, you can read the tool’s description or reviews.

- Durability

It would be best to consider durability when choosing tools for inspection because of frequent use and considerably high purchase price. This feature is crucial since it also determines accuracy and consistency. Checking for high-quality materials such as tungsten carbide, hardened steel, and ceramic used to make the tools is one of the ways to determine durability. Robust construction can also help you, enabling the precision tool to withstand the strain from frequent use.

Accuracy is crucial in construction or production because it saves you from high costs caused by errors. In addition, it enhances efficiency and keeps your customers or clients satisfied. However, you must get the right precision tools to enjoy the benefits. Therefore, it will help to consider the features you have read here when choosing.