A significant factor in the method of regeneration of diesel particulate filters (PDF) is an exhaust gas pressure sensor (EBP). Exhaust gas pressure sensors (EBP). The DPF traps Particulate matter (PM) and soot to avoid environmental damage.

Table of Contents

The EBP Sensors: What are these and their features?

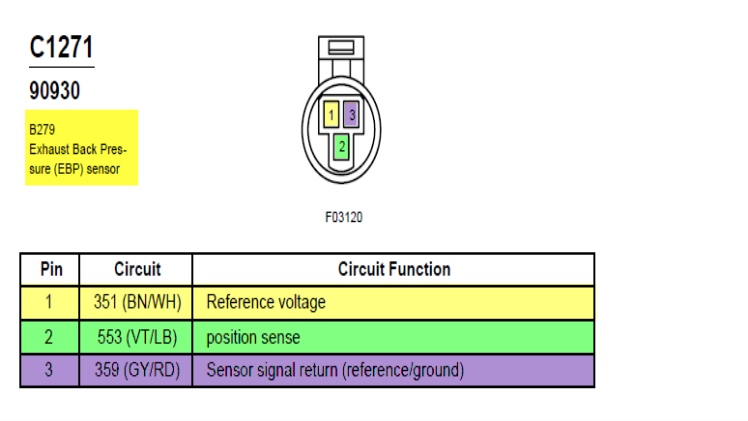

The EBP controls the pressure before and after the DPF to detect the pressure difference caused by PM build-up (soot). The ECU is then directed to regenerate PDF. The set includes ten exhaust gas pressure sensors on UK roads that cover more than 3.5 million vehicles. In the regeneration of the Diesel Particulate Filter, the EGPS plays a key role, and so to ensure optimum lifespan, all sensors are installed to the original equipment requirements. The EBP sensor is a variable condenser sensor which uses an exit back pressure referral 5 volts from the PCM and then returns an analogue linear signal. This data is used to modify several engine functions.

It all went well and well until the clean, strong diesel didn’t work or generated the power it needed. The days when a fuel pressure meter was hooked or an injection line was cracked or two, the weak cylinders were lost. We cannot see, feel or hear what the fuel injection system regulates now in the electronic era.

The EBP sensor provides PCM feedback to control VGT and EGR and can cause drivability problems when functioning incorrectly. However, your truck is a model from 2003, and the EP sensor has been deactivated unless you still have the original engine calibration. In 2004, the sensor was problematic when calibration changes were issued, and the data from other sensors were “shut off for backpressure measurement. What many people tend not to understand is that while the sensor data is no longer used, the sensor is STILL wired and readable to the PCM. Any failure or wiring of the sensor may also impact other engine sensors that share those circuits. This means that another sensor can have a short sensor or reference voltage wiring.

Zabbix Pressure Sensors

The only sensors manufactured in OE lines, packaged in OE quality control and sold straight to the aftermarket are directly available on the market from the OE supply base. EBP sensors (Exhausted Back Pressure) live in one of the most challenging conditions in which the sensor can be interfaced with an oily soot-rich hot engine exhaust. ZibbixTM Sensors use state of the art, proprietary and high-quality products on the market for periods. The EBP Zibbix sensors are designed to be more robust and durable than OEM sensors. Higher temperatures and more challenging conditions are needed.

The Sensor Zibbix incorporates the latest materials in an electric connector for superior resistance and corrosion, advanced internal technology and improved Thermoplastic materials Dupont which can be used in the engine compartment for a more extended period. Finally, the components are equipped with an o-ring on a crimp joint, pushed into the metal box of the sensor and crimped robotically for uniformity. Inferior RTV silicone and other adhesives were used in the OE components (and mostly aftermarket components) put in a bunch along the crimp joint to create their environmental stick. Our o-ring construction produces a 360° static compression seal, which is far higher than any other ambient seal found in these sensor forms.

End Words

Over time, moisture reaches the sensor and contributes to short circuits and degradation without an excellent environmental dynamic. Zabbix EBP sensors are provided by leading industry.