Turbines are at the heart of many critical industries, from power generation to aviation. Their performance, reliability, and efficiency depend on the seamless operation of countless internal components. The labyrinth seal is one of the most vital yet often overlooked. Specifically designed for high-speed rotating equipment like turbines, labyrinth seals provide an essential function: minimizing leakage while allowing the machinery to operate smoothly.

Table of Contents

What Are Labyrinth Seals?

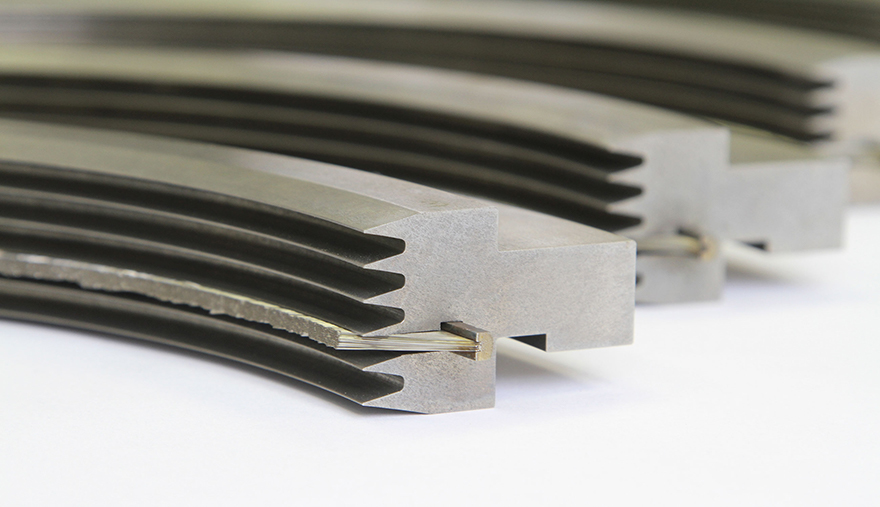

A labyrinth seal is a non-contact sealing solution that uses a series of ridges, grooves, or teeth to create a complex pathway for fluid or gas. Instead of physically blocking leakage, it restricts the flow by forcing it through multiple turns and pressure drops. This design is especially effective in turbines, where high temperatures, speeds, and pressures demand reliable sealing without introducing friction or wear.

Unlike contact seals, labyrinth seals avoid direct shaft contact, generating less heat, reducing wear, and lasting longer. These qualities make them ideal for turbine applications, where efficiency and reliability are non-negotiable.

Why Turbines Depend on Labyrinth Seals

Turbines—steam, gas, or jet—operate in extremely demanding conditions. They face risks like fluid leakage, contamination, efficiency loss, and even mechanical failure without proper sealing. Labyrinth seals address these issues by:

- Reducing leakage: They maintain system efficiency by keeping steam, air, or gas confined within the turbine casing

- Protecting components: They help safeguard delicate turbine parts by preventing contaminants from entering

- Enhancing efficiency: Reduced leakage means turbines can operate at peak performance, saving energy and lowering operational costs

- Prolonging equipment life: Labyrinth seals minimize wear on the shaft and surrounding components with their non-contact design

In short, labyrinth seals are not just accessories—they are key enablers of turbine reliability and performance.

Types of Labyrinth Seals in Turbines

Different turbine applications call for variations in labyrinth seal design. Some common types include:

- Straight-through labyrinth seals: The simplest design uses a series of ridges to slow leakage.

- Stepped labyrinth seals: Incorporate varying ridge heights to create more turbulence and resistance against leakage.

- Interlocking labyrinth seals: Offer enhanced sealing by overlapping ridges and grooves, increasing the complexity of the leakage path.

Each design can be customized depending on the turbine’s operating environment, pressure levels, and speed.

Materials Used in Labyrinth Seals

Material selection is critical when designing seals for turbines. These components must withstand high temperatures, corrosive environments, and extreme rotational speeds. Common materials include:

- Stainless steel: Durable and resistant to corrosion, ideal for steam turbines

- Nickel-based alloys: Withstand higher temperatures and aggressive environments, which are common in gas turbines

- Graphite composites: Provide self-lubricating properties and are excellent for reducing friction in extreme conditions

Manufacturers ensure seals deliver maximum performance and durability by selecting the right materials.

The Role of Advanced Manufacturing

The evolution of manufacturing technologies has transformed labyrinth seals for turbines. Today’s seals benefit from:

- CNC machining: Ensures high precision in the intricate ridges and grooves that define labyrinth seals

- Additive manufacturing (3D printing): Allows more complex geometries and faster prototyping

- Surface treatments: Advanced coatings improve wear resistance and extend service life

These innovations enhance seal reliability while reducing costs and lead times.

Maintenance and Lifespan

While labyrinth seals are highly durable due to their non-contact design, they are not maintenance-free. Over time, erosion, fouling, or thermal distortion can reduce their effectiveness. Regular inspections during turbine overhauls are essential to ensure seals remain in optimal condition. Replacing or refurbishing seals at the right time prevents efficiency losses and avoids costly downtime.

Benefits Beyond Sealing

Labyrinth seals for turbines do more than prevent leakage. They also contribute to:

- Energy savings: Reducing steam or gas losses improves overall system efficiency

- Safety: Containing fluids at high pressures reduces the risk of dangerous leaks

- Sustainability: Improved efficiency means less fuel consumption and lower emissions

These benefits cannot be overstated in industries like power generation and aviation, where energy efficiency and sustainability are critical.

A Small Component with a Big Impact

Though small compared to the massive turbines they support, labyrinth seals play a critical role in keeping these machines efficient, reliable, and safe. Their non-contact design, adaptability, and durability make them indispensable in one of the most demanding engineering environments. Investing in high-quality labyrinth seals for turbine operators is not simply about sealing—it’s about protecting equipment, improving efficiency, and ensuring long-term success.