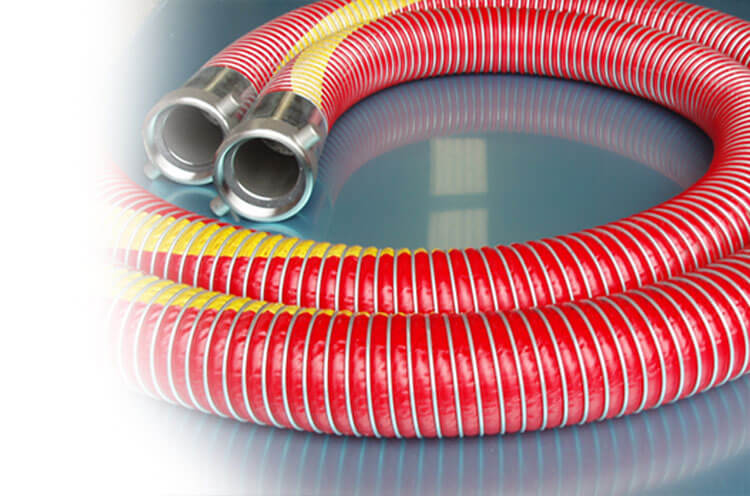

There are several types of flexible hoses out there to choose from, including stainless steel hoses. While these hoses are made from braided steel and often have a polymer coating, composite hoses have a more complex and unique construction.

A composite hose is made from multiple layers of polymer materials wrapped around a wire helix, with another spiral of metal wire binding the outside. This follows mandrel wrapping principles to strengthen the hose while maintaining flexibility.

This type of flexible hose is a popular preference in many industries, for many reasons. Let’s take a look at some of the biggest benefits of composite hoses, and how these aspects work together to make them the best choice for a variety of uses.

Table of Contents

1) Flexible and lightweight

The way that composite hoses are constructed gives them a low bending radius – only three times their internal diameter. This makes it much easier to manoeuvre these flexible hoses into the desired positions and places, including smaller areas.

Since there’s no welding or sealant holding a composite hose together, it’s less likely to crack or burst than other hoses assembled in such a way. The layers of a composite hose slow down leakage, holding back a breach until it can be addressed.

Not only are they extremely flexible, but composite hoses are also incredibly lightweight. They can be many times lighter than other hoses, such as braided steel. This means they’re easy to handle during storage, set-up, and further operations.

2) Multi-purpose

Flexible hoses are important for transferring substances as part of many major industries. Composite hoses are often the most efficient choice due to their many strengths, not least their customisability. They can transport a wide range of liquids and gases.

Composite hoses are often used in the fuel sector, from petroleum refineries to road tankers. They’re common in food processing and pharmaceutical plants, plus the agriculture and aerospace industries, and even in the military.

These hoses are also used for ship to shore purposes – loading or unloading ships while they’re in port. The flexible and impermeable tubes are integral to well and pump systems. They can safely contain high-value or hazardous materials.

3) Versatile design

Composite hoses are not only physically flexible, but also flexible in design. You can order custom composite hoses according to the specific mechanical requirements of your industry, and your chosen manufacturers will produce the modified hoses.

The wire helixes can be made of different types of steel, aluminium, or other metal alloys. The thermoplastic layers can be fabrics, films, or a mix of the two. These can be made from polyamide, polypropylene, polyester, or polytetrafluoroethylene.

You must assess the needs of your operations prior to ordering bespoke composite hoses, so that they meet all the necessary standards. Suitable materials depend on the substance the hoses will convey, length, end fittings, and weight and temperature capacities.

4) Robust and durable

As mentioned previously, composite hoses are strongly made to avoid bursting under pressure. The inner pipe can stretch and expand while the rigid shell protects it against abrasion, reducing the risks of environmental or age-related wear and eventual failure.

The multiple layers that make up composite hoses mean that potential substance leaks have a long way to go before they can make it out of the pipe, as there isn’t a direct path to the outermost layer. You’ll be able to see any build-up at the seams before it can get there.

The last thing anyone wants during mechanical operations is a rupture, especially if the hose is transporting a hazardous material like toxic gas or corrosive chemicals. Their high tensile strength and durability ensure that composite hoses will have a longer service life.

5) Highly resistant

Composite hoses have high temperature, pressure, and vacuum resistance, as well as withstanding corrosive substances without eroding. They are resistant to negative and positive pressures, again ensuring that the pipe will never suddenly burst under pressure.

Their composite materials can also endure extreme temperatures without melting or cracking, maintaining their function and capabilities even in boiling hot or below freezing environments. They should neither harden nor soften in fluctuating temperatures.

The properties of particular composite materials allow their hoses to have high corrosion resistance, too. While standard pipes may erode from corrosive substances, like crude oils, solvents, and liquid gases, composite hoses will withstand the hazardous materials.

6) Safe and reliable

Safety is crucial in industries where large volumes of potentially dangerous substances are being moved or stored. As composite hoses are less likely to corrode, and gathered droplets will notify you of a leak before it can get to a critical point, these hoses are very safe.

You can rely on them to last for many years without fatigue if they’ve been appropriately designed and constructed for your specific purposes. The materials used are also flame retardant, preventing explosions and the spread of fire if flames do occur.

The conductive performance of composite hoses also means that if a flammable medium generates static electricity through friction inside the pipe, a built-in electrostatic discharge function will export the electricity before it can build up enough to spark a fire.

Summary: why you should buy composite hoses

Cost-effective, user-friendly, sturdily reinforced with decreased permeability and excellent compatibility with a variety of substances and states – we could go on and on about the benefits of this strong and safe type of flexible hose.

We’ll stop here, as you can already see from the list of extensive advantages in this article that composite hoses are a winning design. If you’re in need of flexible hoses for your business, always source them from a qualified provider.

A reputable flexible hose manufacturer will gladly work with you to create a composite hose that meets all of the necessary mechanical requirements, ensuring that you can operate safely for years to come with durable and reliable hoses.